Hospital ICU Department uses HydroFLOW® Water Treatment

From homes to hospitals with HydroFLOW®.

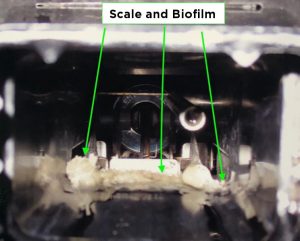

Ice Making Machines are used at many kinds of settings usually in catering and hospitality. This hospital in Kentucky, USA wanted to improve the performance of the Hoshizaki Ice maker at the Intensive Care Unit. The Ice Maker suffered from limescale and biofilm growth on the Ice maker Tray and Ice chute

The Ice Maker ice dispenser before HydroFLOW® water treatment. Limescale and bio build-up is normal part of running a well-used ice maker

The 90-day product evaluation was proposed by Hospital Management and overseen by HydroFLOW® USA representative Bob Soffel of Critical Environment Solutions. The trial took place between December 2018 to March 2019.

The HydroFLOW® HS38 was installed on the cold supply to the Hoshizaki Ice maker at the Intensive Care Unit

HydroFLOW® was easy to install onto cold feed to Ice Maker

Conclusion of report drawn up following the 90-day product evaluation of The HydroFLOW® HS38:

- “The HydroFLOW® device gradually removed existing scale and biofilm from inside the ice maker and and kept it clean”.

- “The HydroFLOW® device minimized the risk of disease outbreak, such as Legionella”

- “The projected invested (ROI), due to lessened maintenance is under a year”

- “Maintenance saved so projected ROI under a year”

It is a very different story than the picture before where scaling and bio is clear. 90 days evaluation photo after HydroFLOW® installation

Control of limescale is also important for the prevention of Legionnaires Disease. As noted in the L8 agreed code of practise for Legionnaires Disease, hardness scale forms a barrier to treatment chemicals and may provide microbial habitat. (L8-1, 1.9). Heavily scaled heat exchange surfaces make it more difficult to maintain the higher temperatures needed to reduce legionella risk.

Another important aspect for Legionella management is the formation of biofilm on surfaces. Biofilm can impair heat transfer efficiency, cause severe localised corrosion and encourage the growth of legionella and should be considered as high-risk contamination (L8-1, 1.9).

Limescale can become a problem in Ice Making Machines. During the process of making Ice, scale forms over time. This limescale accumulation can hamper operation and diminish its effectiveness.

Limescale causes the Ice cubes produced by Ice making machine to look cloudy and dirty. In all areas of catering and hospitality, this diminishes the experience of the customer. By using HydroFLOW®, the clarity of ice cubes we all come to expect is maintained.

HydroFLOW® is easy to retrofit and has minimal operation costs making ROI achievable very quickly. There is no need for maintenance, and all components are built to last. There are so many plusses that makes this the eco and sustainable product to invest in right now.

Ice job HydroFLOW® !