HYDROPATH IS A British Company operating around the world.

Award winning HydroFLOW® is the well-known no-chemical solution for limescale and biofouling in HVAC.

Equally HYDROPATH has astounding results in documented case studies in industry. Here I want to highlight another speciality of our clean tech solutions. In this application HydroFLOW® is used in industry to make savings with chemicals, maintenance and equipment costs.

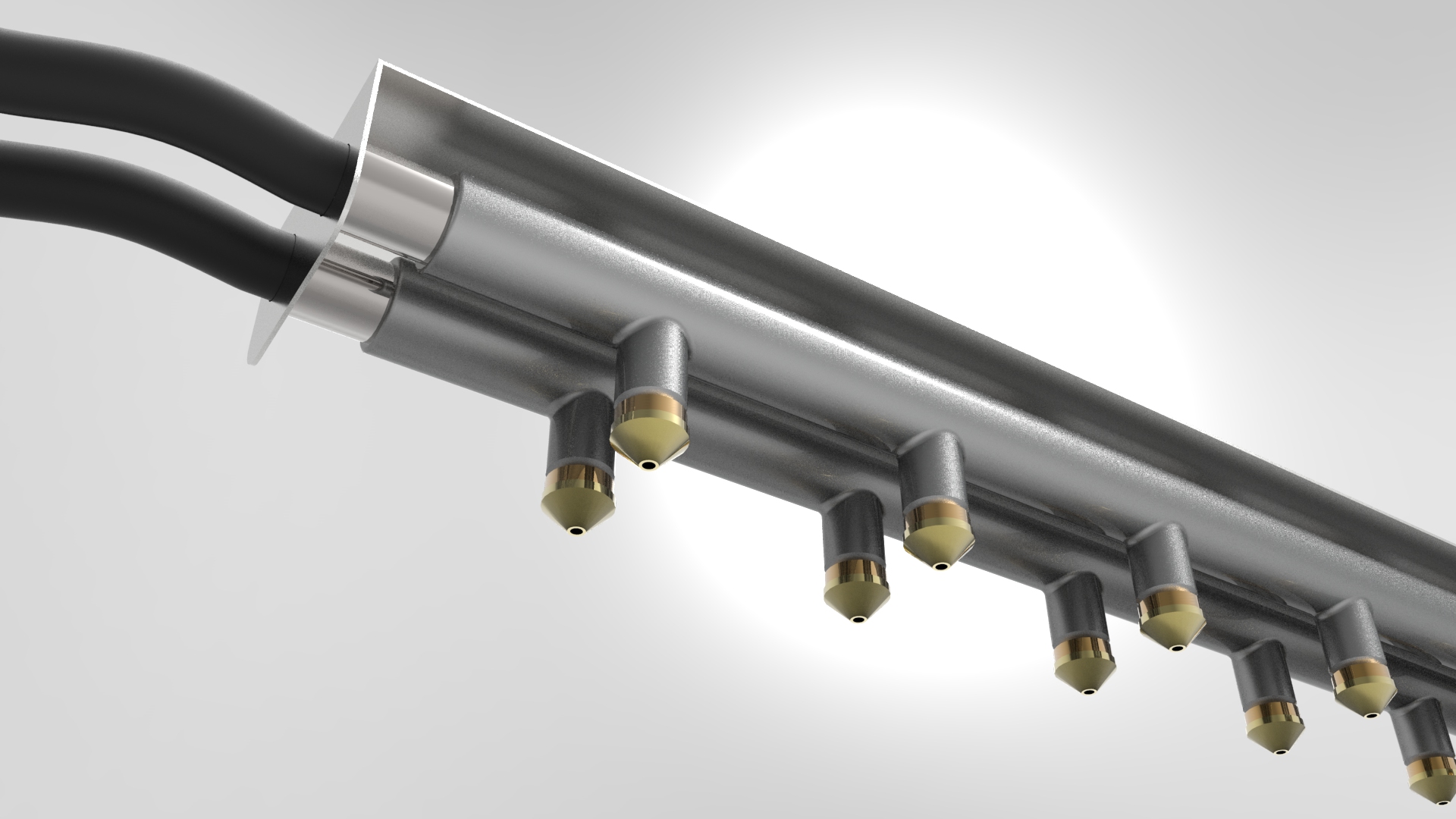

Spray heads, spray bars, spray nozzles, misting systems, humidification systems, irrigation systems, wash systems, shower nozzles can block up with limescale and experience bio-fouling issues.

HydroFLOW® works on all types of spray nozzle systems in Manufacturing, Steel mills, Aluminium processing, Paper factory, Cement factory, Food Production, Agriculture, Restaurants, Retail and Carwashes.

In the case studies below, you will find evidence of substantial chemical savings for cleaning and maintenance, water savings, quick turnaround ROI as well as energy savings and help with longevity of equipment.

Case Study 01

Location

Hatchery, Netherlands

Problem

Limescale caused blockages and maintenance to keep the spray system at optimal performance.

Results with HydroFLOW®

“Since we have the HydroFLOW® units we have circa (ca.). 60% less work on the nozzles . The scaling in the spray cabinets is ca. 50% less than before the HydroFLOW® units.“

Case Study 02

Location

Steel Mill, Ontario, Canada

Problem

Limescale build-up, and blockages in the spray bar nozzles and recirculation piping system production schedule would be interrupted due to spray failures, clogging and maintenance. Supply piping would become blocked requiring mechanical auguring and high pressure sprays to remove limescale build-up and blockages. Spray nozzles and bars required mechanical and chemical cleaning using manpower and hazardous chemicals. Customer estimates system maintenance and replacement costs to be approximately $ 35,000.00 per year.

Results with HydroFLOW®

- Client “the results were unquestionable!!”

- Supply line which was at 65% blockage has been reduced to 10% blockage

- The system has now been running for 1 year from installation with no shutdown or blockages during this time, only inspections have been required.

- ROI (return on investment) was calculated at 3 months for this application

- Annual maintenance and equipment savings $ 35,000.00

Case Study 03

Location

Grocery Store with 3000 stores, USA

Problem

In this case, misting systems are used to keep produce display cases clean and clear. Scale and scum accumulation within the Mister system nozzles.

Results with HydroFLOW®

- Limescale build-up on display, signage and nozzle screens was barely negligible

- Removal of scum or limescale was easy to clean or wash away.

- Maintenance was reduced by 75%

- ROI was achieved within 3 months after installation.

Award Winning Technology

Please contact us today at sales@hydropath.com to find out how we at HYDROPATH can help you meet your CSR goals, save money and make that all important difference.

Since 1992 HYDROPATH has been addressing some of the most persistent problems that occur in water systems such as Limescale and Biofouling. HydroFLOW® is a patented, no-chemical water treatment technology and in 2021 HydroFLOW® was recognised by Solar Impulse Foundation as a clean technology, both profitable (it saves the customer money) as well as sustainable (saving on water, energy and chemicals.)

7 reasons to choose HydroFLOW®

Easy to install

It’s simple to install under the boiler (on the cold inlet pipework)

Low operation cost

It’s powered directly from the boiler PCB ( no external power source required) with a three- metre cable supplied (only costs approximately £1.50/year to operate)

Easy to retrofit

It clips onto the pipework via a patented clamp system (no need to cut the pipework or drain the water)

Sustainable – no chemicals

It’s environmentally friendly as it does not use any chemicals (competitors use electrolytic types that have zinc sacrificial anodes which release small amounts into the water)

Patented

It has a patented electronic water conditioner technology where the signal propagates around the entire hot and cold water pipework, which is unique to Intergas as we don’t use plate-to-plate heat exchangers so the waterway is always open allowing the electronic signal to flow with an uninterrupted signal.

New/existing limescale

The signal causes any limescale present to bond together (cluster) and, when subjected to heat, it will crystalise and travel out of the pipework with the water flow, preventing any build-up or damage occurring. The signal will also breakdown any existing limescale that has adhered to the internal pipework eventually clearing over time, subject to flow rate, temperature and hardness.

Signal travels in all directions

The signal can flow up and downstream of the HydroFLOW HS38, providing there is a clear path within the waterways, however we recommend it is fitted closest to the heat generating source for the best results.