Waste Water Treatment with HydroFLOW®

HydroFLOW® enhances wastewater treatment by managing struvite scaling, improving solid-liquid separation, and reducing chemical use. Its non-invasive, eco-friendly technology supports smoother operations, lower maintenance, and greater long-term efficiency in treatment processes.

Enhancing Wastewater Treatment Efficiency with HydroFLOW®

HydroFLOW® optimises wastewater treatment by addressing struvite scaling, improving solid-liquid separation, and minimising chemical dependency. By influencing mineral behaviour, it helps maintain efficient flow in wastewater infrastructure, reducing blockages and maintenance demands. Its electronic flocculation technology enhances polymer efficiency, while also lowering the need for anti-foaming agents, leading to cost savings and smoother operations. With quick, non-invasive installation and a sustainable, chemical-free approach, HydroFLOW® provides an eco-friendly and cost-effective solution for improving wastewater treatment performance and long-term reliability.

Key Waste Water Treatment Industry Applications

Struvite

Treats struvite buildup in sludge handling, centrate lines, and digester systems.

Protects pipes, pumps, and dewatering equipment from scale-related failures.

Reduces chemical and mechanical cleaning interventions in WWTPs.

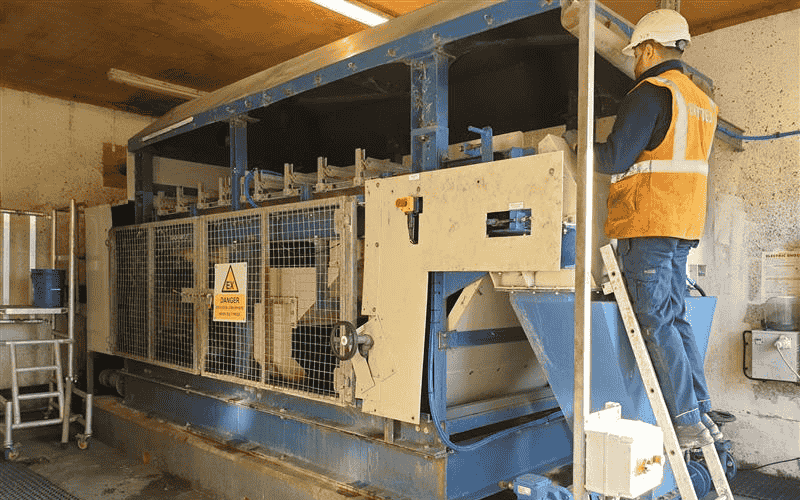

Polymer Reduction in Dewatering

Improves dewatering efficiency in sludge treatment plants.

Reduces polymer consumption while maintaining separation performance.

Lowers sludge disposal costs and boosts water recycling potential.

Centrifuges

Enhances separation efficiency in sludge dewatering and filtration systems.

Treats scale and biofilm in wastewater treatment centrifuges.

Supports more eco-friendly, chemical-free water treatment practices.

Dissolved Air Flotation (DAF)

Optimises DAF systems for industrial and municipal wastewater treatment.

Lowers polymer and coagulant consumption.

Improves sludge dewatering efficiency and effluent quality.

Other Scaling

Reduces iron, manganese, and mixed scale in treatment tanks and pipes.

Helps protect filtration systems and sludge dewatering equipment.

Supports stable operation in high-solids and nutrient-rich flows.

Limescale

Helps minimise scale in sludge heating systems and filtration units.

Improves flow rates and reduces chemical cleaning.

Supports sustainable wastewater treatment practices.

Biofouling

Reduces biofilm in clarifiers, aeration tanks, and sludge systems.

Improves treatment efficiency and reduces cleaning needs.

Supports non-chemical microbial control in challenging environments.

Flocculation and Filtration

Enhances flocculation in primary and secondary clarifiers.

Improves filtration performance in effluent polishing systems.

Reduces polymer use and extends filter media life.

Cooling Tower

Manages scale and bacterial growth in cooling towers at treatment facilities.

Improves water quality for reuse in industrial cooling applications.

Reduces chemical reliance for system maintenance and operation.

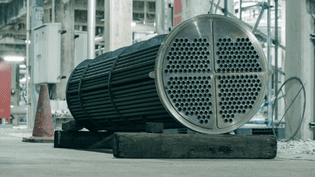

Heat Exchanger

Limits scaling and biofilm in heat exchangers at treatment facilities.

Optimises heat recovery systems for energy-efficient wastewater treatment.

Reduces chemical usage and supports eco-friendly water management.

Heaters and Boilers

Treats scale and biofilm in sludge heating and treatment facilities.

Optimises heat recovery for more energy-efficient wastewater management.

Reduces chemical usage and supports eco-friendly heating solutions.

Pipelines

Minimises scaling and biofilm in wastewater treatment pipelines.

Improves flow efficiency in sludge and effluent transport systems.

Supports eco-friendly water management and treatment practices.

Valves

Reduces scaling and biofilm in wastewater treatment valve systems.

Improves flow efficiency in sludge and effluent transport.

Encourages eco-friendly water management and treatment practices.

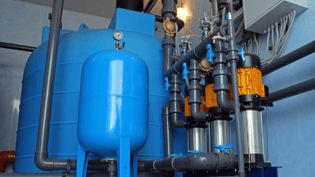

Pumps

Minimises scaling and biofilm in wastewater treatment pump systems.

Improves flow efficiency in sludge and effluent transport.

Supports eco-friendly water management and treatment practices.

Steam Boiler

Helps protect steam boilers used in sludge treatment and water recycling.

Limits scaling and biofilm in steam-based wastewater treatment processes.

Supports eco-friendly steam production with reduced chemical usage.

High Concentration Process

Optimises high concentration sludge treatment and dewatering.

Reduces chemical usage in wastewater concentration processes.

Enhances water recycling potential by improving system efficiency.

Corrosion Control

Safeguards wastewater treatment plant piping and equipment from corrosion.

Reduces biofilm-induced corrosion in high-solids water systems.

Minimises chemical dependency in industrial water treatment.

Reverse Osmosis

Helps optimise RO for wastewater recycling and reuse.

Reduces biofouling and membrane clogging in industrial treatment plants.

Enhances sustainable water treatment with lower chemical dependency.

Filters

Enhances filtration in sludge treatment and effluent polishing.

Reduces biofilm and scaling in wastewater treatment filters.

Supports eco-friendly, chemical-free water treatment practices.

Legionella Treatment

Reduces biofilm and microbial hotspots in sludge and effluent handling systems.

Helps support safer operation of high-temperature treatment systems.

Minimises Legionella exposure for staff and surrounding areas.

Optimising Wastewater Treatment with HydroFLOW®: Reducing Scaling, Chemical Use & Maintenance Costs

Address Struvite Scaling

Struvite deposits can cause significant blockages in wastewater systems, reducing flow rates and increasing maintenance requirements. HydroFLOW® utilises an electrical signal to influence mineral behaviour, helping to keep precipitated material in a powder-like form rather than forming hard deposits. This supports smoother system operation and minimises the risk of obstructions.

Helps manage struvite accumulation to maintain efficient flow

Reduces the likelihood of blockages in wastewater infrastructure

Supports improved system reliability with minimal intervention

Helps lower maintenance demands related to scale buildup

Cuts Polymer Use

Flocculants are widely used in wastewater treatment to help separate solids, but excessive use can increase costs. HydroFLOW®’s electronic flocculation technology helps enhance solid separation, potentially reducing polymer consumption and improving overall treatment efficiency.

Helps optimise polymer use, cutting costs by over 15%

Improves the flocculation process through electronic treatment

Reduces chemical reliance while maintaining treatment effectiveness

Contributes to more efficient and economical wastewater processing

Minimise Anti-Foam Requirements

Excessive foaming in wastewater systems can disrupt operations and require costly chemical treatments to control. HydroFLOW® helps reduce the need for anti-foaming agents, leading to optimised chemical use and lower operational costs.

Helps reduce foaming issues in wastewater treatment processes

Minimises the need for additional chemical interventions

Supports smoother plant operation with fewer disruptions

Lowers ongoing expenses related to anti-foaming treatments

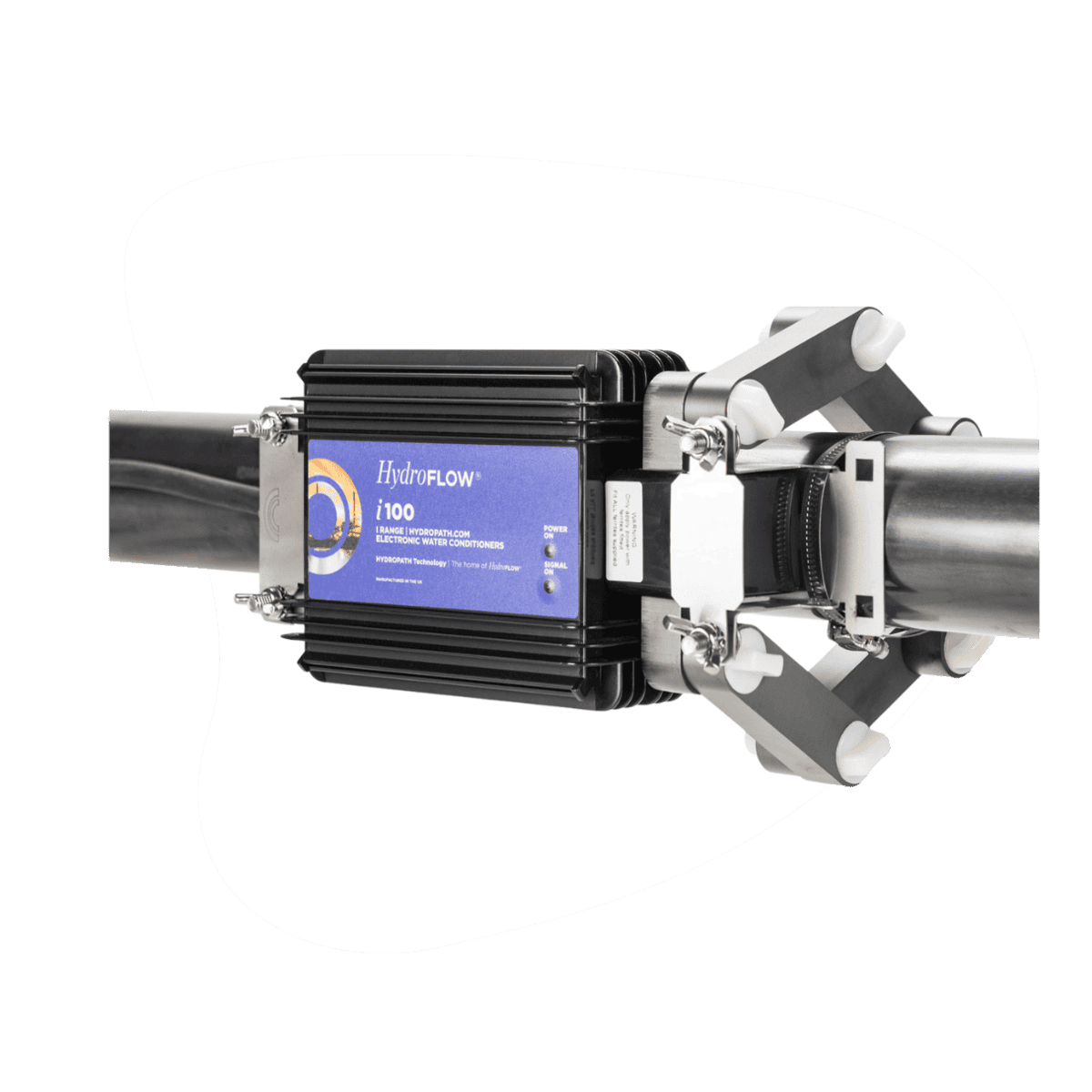

Easy Installation

Many water treatment solutions require extensive system modifications or downtime, leading to costly interruptions. HydroFLOW® is designed for quick and easy installation, fitting around existing pipes without halting operations, ensuring minimal disruption to daily processes.

Installs without cutting pipes or shutting down operations

Compatible with various pipe materials and system configurations

Provides an immediate impact with no major modifications required

Ensures continuous system function with effortless integration

Eco-Friendly and Cost-Efficient

Sustainability and cost-effectiveness are key considerations in wastewater management. By optimising chemical use and improving system efficiency, HydroFLOW® offers a practical, environmentally responsible alternative to traditional treatments, delivering both financial and ecological benefits.

Supports sustainable wastewater treatment with reduced chemical usage

Helps lower operational costs through improved system efficiency

Reduces environmental impact by minimising chemical discharge

Delivers long-term savings and enhanced process reliability

Let’s Enhance Your Waste Water Treatment Systems with HydroFLOW®

Improve Wastewater Treatment with HydroFLOW®. Control scale and struvite build-up in wastewater treatment plants, enhancing efficiency and reducing maintenance downtime. Minimise chemical use with this easy-to-install solution for reliable performance.

sales@hydropath.com

+44 (0) 115 986 9966