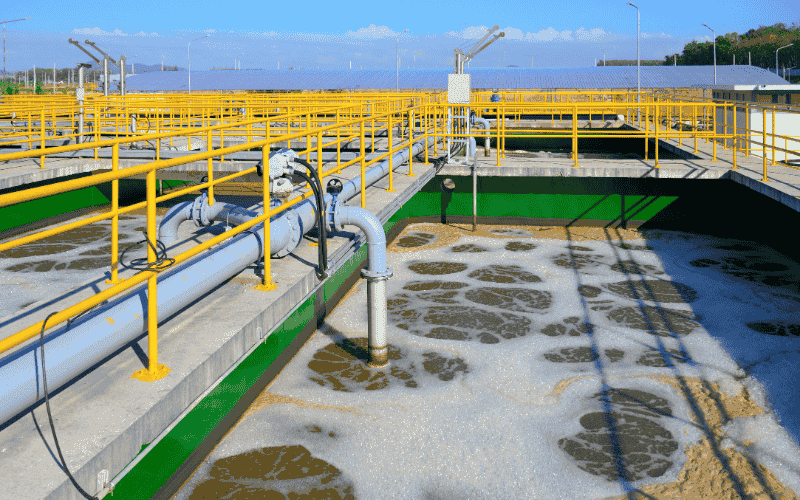

Waste Water Treatment System Applications with HydroFLOW®

HydroFLOW® enhances wastewater treatment by improving separation processes, reducing chemical usage, and preventing scaling due to both limescale and struvite. Our technology supports efficient operation in centrifuges and other dewatering processes, Dissolved Air Flotation (DAF) systems and other pipework and equipment, leading to lower maintenance and operational costs.

Improve Separation, Reduce Chemical Use, and Optimise Wastewater Treatment with HydroFLOW®

Two issues that are particularly problematic in the treatment of waste water are the build-up of struvite or other scaling, and the need to add expensive polymer flocculants to ensure the effectiveness of the dewatering process.

HydroFLOW® electronic water conditioners also offer a non-chemical alternative to attacking mineral scale such as struvite and minimising physical interventions such as high pressure jet washing. HydroFLOW® also optimises sludge dewatering through non-chemical flocculation, allowing a reduction of polymer consumption, and improving separation efficiency in DAF systems, centrifuges, belt presses and other dewatering equipment.

HydroFLOW® keeps equipment running smoothly, minimises maintenance, and supports a more cost-effective and sustainable wastewater treatment process.

Key Applications

Centrifuges

- Limescale on bowls and rotors disrupts balance and reduces separation efficiency.

- Biofilm builds up in chambers, causing contamination and hygiene risks.

- Corrosion damages components, leading to frequent repairs and reduced lifespan.

- HydroFLOW® treats scale, biofilm, and corrosion to keep centrifuges clean and efficient.

Struvite

Treats struvite buildup in sludge handling, centrate lines, and digester systems.

Protects pipes, pumps, and dewatering equipment from scale-related failures.

Reduces chemical and mechanical cleaning interventions in WWTPs.

Polymer Reduction in Dewatering

- HydroFLOW® improves flocculation, reducing polymer needs and boosting dewatering efficiency.

- Excessive polymer use increases costs and sludge volume.

- Scale and fouling in equipment reduce throughput and require frequent cleaning.

- Reduces need for anti-foaming agents used to treat polymer overdosing.

Dissolved Air Flotation (DAF)

- HydroFLOW® treats scale and biofilm, enhances flocculation, and improves DAF clarity and reliability.

- Poor flocculation results in inefficient separation and high chemical usage.

- Scale on diffusers and pipes disrupts air flow and system performance.

- Biofilm clogs components and lowers effluent quality.

See HydroFLOW® in Action - Request a FREE Consultation

Want to see HydroFLOW® in action? We offer consultations, product demonstrations, and expert advice to help you understand how our technology can benefit you.

Get a free consultation today and find the perfect solution for your home or business.

sales@hydropath.com

+44 (0) 115 986 9966