Struvite Applications with HydroFLOW®

HydroFLOW® helps control struvite formation by treating mineral behaviour in fluid systems, minimising the accumulation of hard crystalline deposits. It supports smoother operation, reduces maintenance, and protects key components in wastewater, biogas, and sludge treatment applications.

Managing Struvite with HydroFLOW®

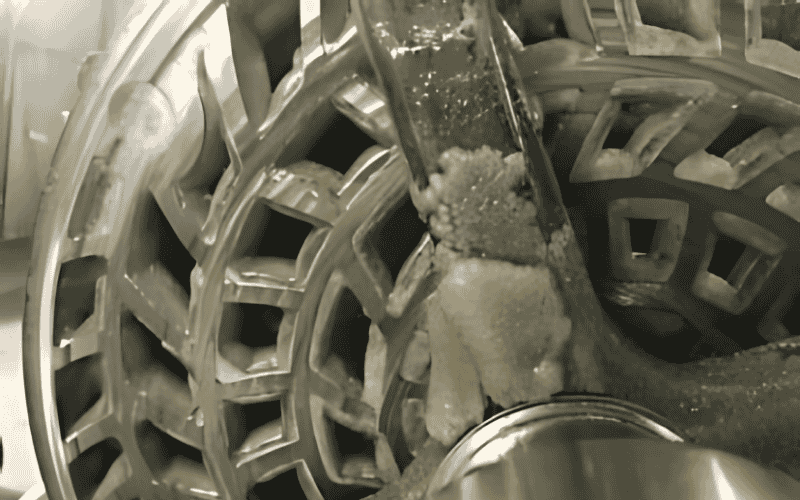

Struvite (magnesium ammonium phosphate) is a crystalline deposit that commonly forms in wastewater treatment plants especially in anaerobic digestion, sludge dewatering, and centrate return systems. It clogs pipes, blocks pumps, coats sensors, and disrupts flow, leading to costly downtime and repairs.

HydroFLOW® offers a non-chemical solution that treats struvite, reducing its ability to attach to surfaces. By altering crystallisation behaviour, HydroFLOW® keeps minerals in suspension so they can be flushed out instead of forming hard, cement-like deposits on the internal surfaces of equipment and pipelines.

Key Industries

WASTEWATER INDUSTRY

- Treats struvite buildup in sludge handling, centrate lines, and digester systems.

- Protects pipes, pumps, and dewatering equipment from scale-related failures.

- Reduces chemical and mechanical cleaning interventions in Waste Water Treatment Plants (WWTPs).

Agriculture Industry

Treats struvite formation in irrigation lines, fertigation systems, and livestock wastewater.

Helps reduce blockages in emitters, pumps, and storage tanks.

Minimises disruption to water flow and reduces cleaning and maintenance frequency.

Swimming Pool INDUSTRY

Treats struvite formation in balance tanks, filtration systems, and backwash lines.

Helps reduce struvite-related blockages in pumps, filters, and circulation pipework.

Minimises the need for chemical descalers and unplanned maintenance in pool operations.

Cooling Tower Industry

Treats struvite deposits in recirculation loops, sump areas, and heat exchange surfaces.

Helps reduce scaling on fill media, nozzles, and pipework.

Minimises manual cleaning, chemical dosing, and unplanned system interruptions.

COMMERCIAL HEATING AND COOLING INDUSTRY

Treats struvite build-up in closed-loop and open-loop HVAC systems.

Helps reduce fouling in heat exchangers, buffer tanks, and circulation lines.

Minimises maintenance needs, system inefficiencies, and chemical cleaning cycles.

STEAM PRODUCTION INDUSTRY

- Reduces struvite risks in anaerobic digestion plants integrated with steam production.

- Treats scaling in sludge-to-energy heat exchangers and pipework.

- Supports efficient operation of renewable steam generation systems.

FOOD INDUSTRY

- Minimises struvite formation in wastewater treatment and organic waste digesters.

- Helps in keeping pipes, sensors, and centrifuges clean in food industry AD systems.

- Improves operational consistency in high-nutrient effluent environments.

Marine INDUSTRY

- Treats struvite in marine wastewater holding and processing systems.

- Helps protect pipes and pumps in shipboard compact treatment units.

- Reduces maintenance frequency and manual cleaning on vessels.

HOTEL INDUSTRY

Treats struvite build-up in greywater systems, laundry discharge lines, and wastewater infrastructure.

Helps reduce scaling in plumbing, pumps, and hot water circulation systems.

Minimises maintenance disruptions and supports smoother facility operations.

MINING INDUSTRY

Treats struvite accumulation in process water, tailings lines, and wastewater treatment systems.

Helps reduce scaling in pumps, pipelines, and processing equipment.

Minimises maintenance downtime and reliance on aggressive chemical cleaning.

HydroFLOW® Solutions for Struvite: Scaling Control, System Protection, and Reliable Performance

Treats Struvite Crystallisation in Pipes and Pumps

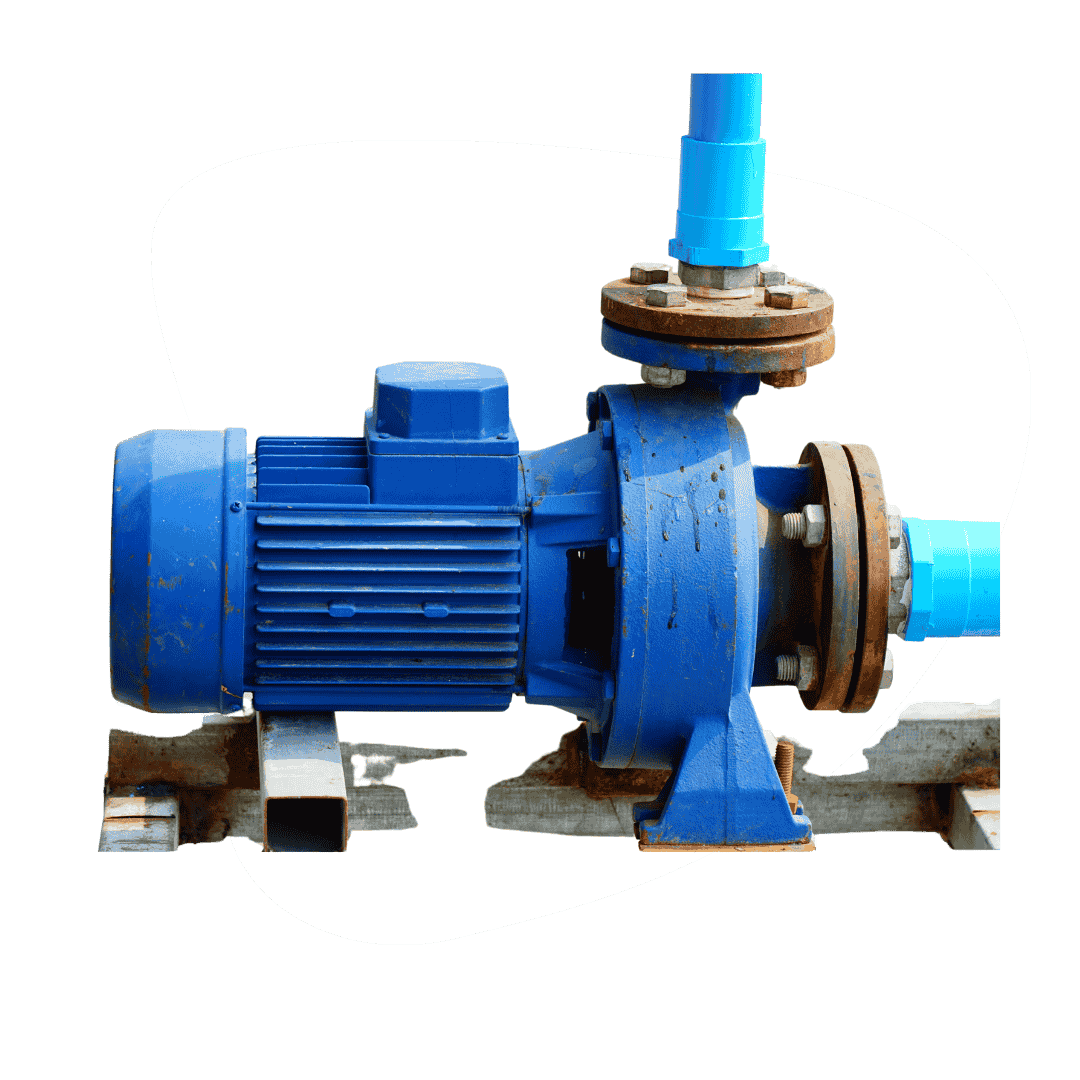

Struvite forms in regions of turbulence, temperature shift, or pH change especially in return lines and pressurised systems. HydroFLOW® helps prevent nucleation on surfaces, keeping pipes clear and pumps functioning reliably.

Treats struvite buildup in sludge and digestate return lines

Minimises blockages in pumps, valves, and narrow pipe sections

Helps maintain consistent flow and system reliability

Reduces the need for mechanical cleaning or hydro-jetting

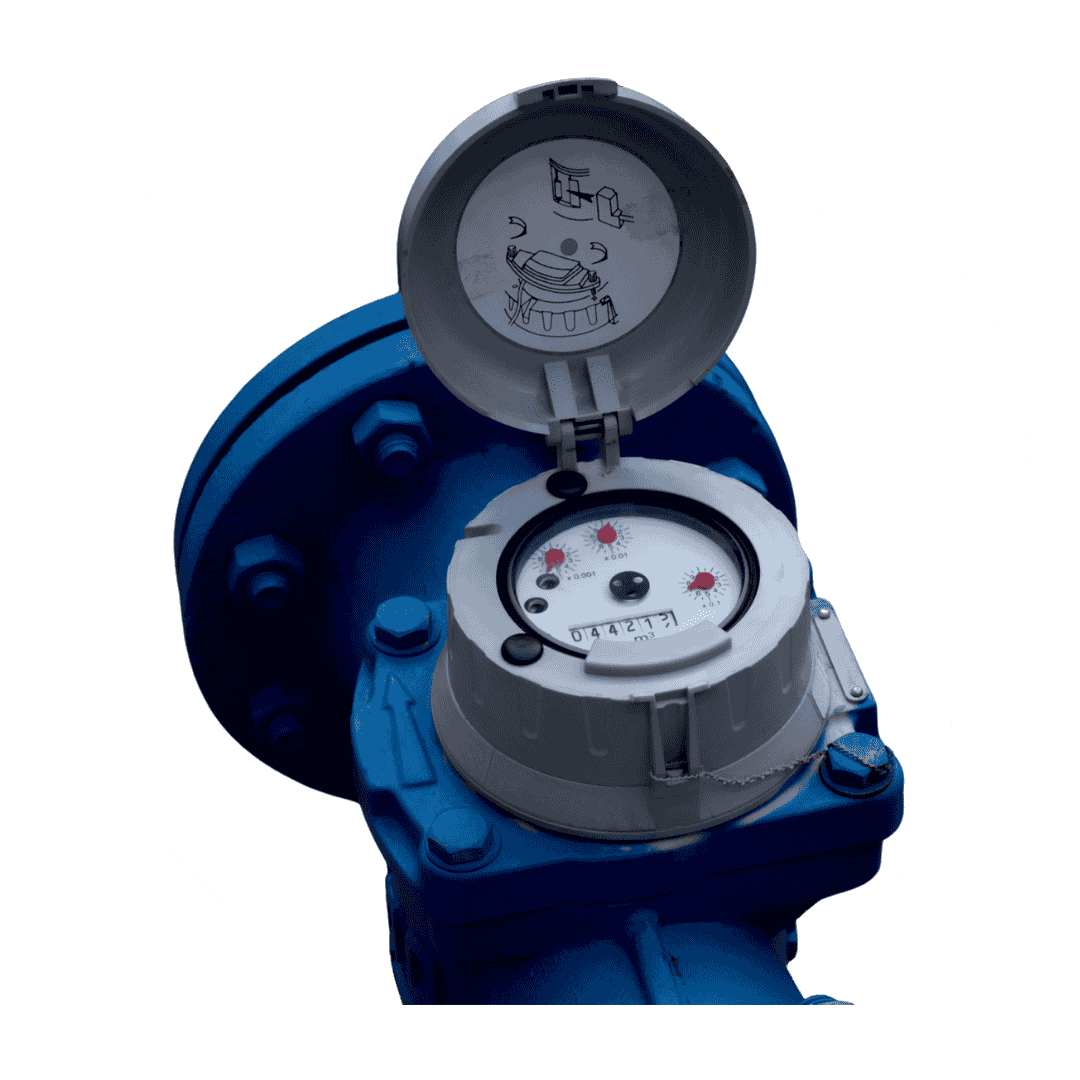

Reduces Scaling on Sensors, Nozzles, and Dewatering Equipment

Struvite deposits interfere with level sensors, flow meters, spray nozzles, and screw presses. HydroFLOW® reduces surface adherence of crystal particles, supporting cleaner operation and more accurate readings.

Protects sensitive instrumentation from scaling interference

Minimises deposit buildup in screw presses, centrifuges, and belt presses

Improves the efficiency of sludge processing equipment

Reduces manual cleaning and unplanned downtime

Supports Improved Water Flow and Pipe Longevity

Struvite constricts internal pipe diameter, increasing pressure and wear on pumps and fittings. By reducing deposit formation, HydroFLOW® maintains optimal pipe capacity and extends infrastructure lifespan.

Minimises gradual flow reduction caused by crystalline deposits

Reduces the risk of pressure surges and pipe strain

Protects both metal and plastic pipe materials

Extends the service life of high-value components

Reduces Chemical Use and Descaling Interventions

Traditional methods for managing struvite include acid washing, mechanical cleaning, or expensive chemical inhibitors. HydroFLOW® provides a sustainable alternative that reduces or eliminates reliance on these reactive treatments.

Minimises or eliminates use of costly chemical struvite inhibitors

Reduces acid dosing and associated safety risks

Simplifies plant maintenance and cleaning regimes

Supports compliance with environmental and safety regulations

Improves Plant Efficiency & Reduces Downtime

Struvite issues often lead to unexpected plant shutdowns or reduced throughput. HydroFLOW® helps maintain smooth operation across digesters, dewatering lines, and recycle streams improving overall system performance.

Ensures stable operation of digestate and sludge transport systems

Reduces blockages that impact treatment capacity

Increases reliability of dewatering and nutrient recovery systems

Lowers maintenance budgets and total cost of ownership

Let’s Enhance Your Systems with HydroFLOW®

Whether you’re treating scale, controlling biofilm, or improving filtration, HydroFLOW® offers a reliable, chemical-free solution to keep your systems running at their best.

From residential to heavy industry, our award-winning technology supports cleaner operations, reduced maintenance, and long-term sustainability.

Get in touch with us today to discuss how HydroFLOW® can optimise your application.

sales@hydropath.com

+44 (0) 115 986 9966