Commercial Water Treatment with HydroFLOW®

HydroFLOW® provides advanced water treatment solutions for commercial properties, improving energy efficiency and reducing maintenance costs across various industries. From hotels and restaurants to factories and office buildings, our innovative technology enhances the performance of water systems while minimising downtime and operational expenses.

Protecting Your Business with Proven Technology

For over 30 years, Hydropath has been at the forefront of eco-friendly water treatment. Our patented technology supports the efficient operation of water systems by addressing issues related to scale, bacteria (e.g. Legionella), biofilm, and algae without the need for chemicals or salts. In commercial settings, untreated water can lead to costly repairs, reduced efficiency in heating and cooling systems, and increased energy consumption. HydroFLOW® offers a sustainable and cost-effective way to maintain your business water infrastructure.

Common Problems in Commercial Water Systems

Cooling Tower

-

Scale and biological fouling in HVAC cooling towers for offices, hotels, or retail complexes.

-

High blowdown rates and increased water bills.

-

Legionella concerns if biofilm is left unaddressed.

-

HydroFLOW® helps by treating recirculating water to minimise scale crystals and disrupt biofilm, helping meet safety and efficiency goals.

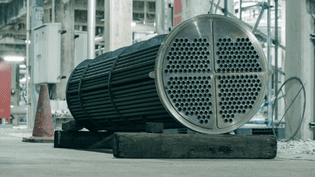

Heat Exchanger

-

Scale or sludge buildup in hot water loops or commercial HVAC exchangers.

-

Reduced temperature control or high utility bills.

-

Operational shutdowns for mechanical descale.

-

HydroFLOW® helps by constantly treating the circulated water, reducing deposit formation and preserving heat transfer.

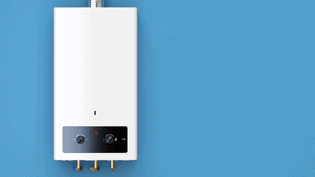

Heaters and Boilers

-

Limescale in hot water boilers, leading to poor heat transfer and increased fuel usage.

-

Frequent breakdowns or partial system failures (e.g., no hot water in a restaurant).

-

Revenue loss from unexpected downtime and high repair bills.

-

HydroFLOW® helps by reducing scale on internal surfaces so commercial boilers maintain efficiency and reliable service.

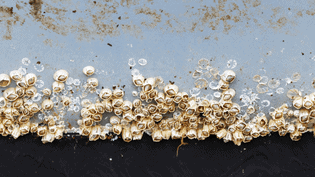

Limescale

-

Scale in dishwashers, water heaters, or coffee machines, causing breakdowns or downtime.

-

Increased operational costs from frequent chemical descaling.

-

Customer dissatisfaction due to visible spots on glassware or slow hot-water service.

-

HydroFLOW® helps by treating limescale in real time, lowering equipment downtime and preserving consistent water quality.

Biofouling

-

Slime or algae in HVAC loops, hot water recirculation, or dishwashing lines.

-

Greater chemical usage and more maintenance intervals.

-

Possible health/hygiene issues or unpleasant odours.

-

HydroFLOW® helps by disrupting biofilm adhesion, reducing the frequency of chemical disinfectants and flushes.

Other Scaling

-

Staining on dishware or coffee machines from iron-laden water.

-

Spotty glass and fixtures that frustrate customers.

-

Frequent acid washing damaging equipment.

-

HydroFLOW® helps by making silica/iron less prone to depositing, reducing visible stains and maintaining clearer flows.

Oil Cooler

-

Scale deposits raising cooling costs for commercial chillers or refrigeration systems.

-

Overheating that risks system downtime or product spoilage.

-

Frequent chemical flushes to maintain design specs.

-

HydroFLOW® helps by helping keep heat exchangers cleaner, cutting energy consumption and maintenance cycles.

Electric Resistance & Immersion Heaters

-

Scale forming on immersion elements in large water tanks, slowing heat-ups.

-

Higher energy usage and risk of burned-out elements.

-

Interruptions to hot water supply for customers/employees.

-

HydroFLOW® helps by limiting mineral encrustation on elements, boosting service life and lowering utility costs.

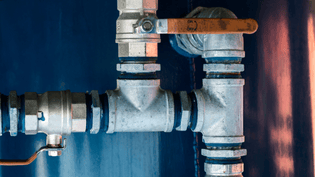

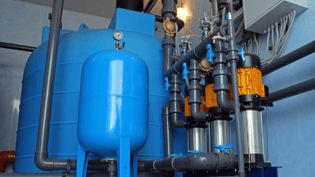

Pipelines

-

Clogging or pressure drops in building plumbing or HVAC loops.

-

Extra pumping costs as blockages accumulate.

-

Inconsistent water distribution to different floors.

-

HydroFLOW® helps by dislodging existing deposits and discouraging new scale, helping sustain stable flow rates.

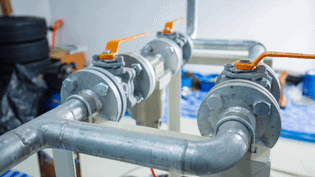

Valves

-

Valves in kitchens, restrooms, or mechanical rooms sticking due to scale.

-

Incomplete sealing leading to leaks or wasted water.

-

Frequent replacements or labour-intensive maintenance.

-

HydroFLOW® helps by treating water so mineral buildup on valve seats and components is minimised, prolonging valve function.

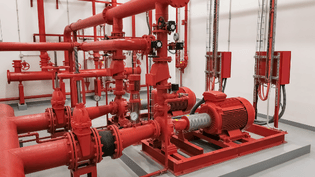

Pumps

-

Scale or biofilm on impellers, causing flow restrictions.

-

Excess load on motors leading to higher energy use or early failure.

-

Costly service calls if water circulation is vital (e.g., cooling, laundry, pools).

-

HydroFLOW® helps by interfering with scale attachment and microbial fouling, helping pumps run more reliably.

Wells and Boreholes

-

Scale/biofouling choking well screens and submersible pumps.

-

Diminishing yield and inconsistent water quality.

-

Expensive well cleanouts or acid treatments.

-

HydroFLOW® helps by making it harder for iron and hardness to stick, preserving stable flow and minimising downtime.

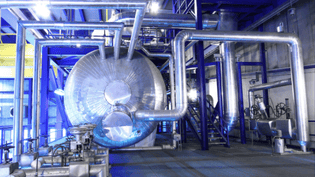

Steam Boilers

-

Scale/biofouling choking well screens and submersible pumps.

-

Diminishing yield and inconsistent water quality.

-

Expensive well cleanouts or acid treatments.

-

HydroFLOW® helps by making it harder for iron and hardness to stick, preserving stable flow and minimising downtime.

Corrosion Control

-

Corrosion under scale in steel or copper pipe loops (e.g., HVAC, potable hot water).

-

Risk of leaks or major flooding events in large buildings.

-

Substantial costs for pipe replacement and business downtime.

-

HydroFLOW® helps by reducing scale and biofilm that speed up corrosion, helping preserve pipe integrity longer.

Reverse Osmosis

-

Membrane fouling in onsite RO setups for high-purity water (restaurants, coffee bars, labs).

-

Frequent shutdowns or reduced water quality if membranes scale.

-

High overhead from early membrane replacements.

-

HydroFLOW® helps by discouraging mineral crystal formation on RO surfaces, cutting membrane maintenance costs.

Filters

-

Sand or cartridge filters quickly blinding from scale or suspended solids.

-

Extra labour for frequent backwashing or cartridge changes.

-

Inconsistent water clarity or taste for customers and staff.

-

HydroFLOW® helps by promoting particle agglomeration and limiting biofilm, so filters last longer and operate more effectively.

Dishwasher

-

Limescale accumulating on heating elements or spray arms, leading to unclean dishes and repeated cycles.

-

Visible spots on glassware, frustrating staff and guests.

-

Increased chemical usage and higher operational costs.

-

HydroFLOW® helps by reducing scale in real time, keeping internal parts cleaner and improving wash quality.

Laundry Machine

-

Scale and biofilm in washers leading to higher detergent usage and subpar cleaning.

-

Equipment breakdowns if the heating element or pump is fouled.

-

Potential odours from bacterial growth in low-temperature cycles.

-

HydroFLOW® helps by diminishing scale deposits and biofilm, cutting detergent costs and machine downtime.

Swimming Pool

-

Scale on pool walls, filters, or heaters, plus algae if biofilm is not controlled.

-

Chemical imbalances leading to high chlorine dosing or frequent shock treatments.

-

Guest complaints about water clarity or strong chemical smells.

-

HydroFLOW® helps by treating recirculating water to limit scale crystal growth and disrupt microbial slime, easing overall pool upkeep.

Legionella Treatment

- Complex hot water loops in offices, hotels, or care homes can harbour legionella in warm/stagnant sections.

- Legal or insurance consequences if testing shows contamination.

-

High overhead from repeated hot-flushing or chemical disinfectants.

-

HydroFLOW® helps by disturbing biofilm surfaces where legionella tends to colonise, helping keep bacterial counts down.

Enhancing Commercial Water Systems by Addressing Limescale and Efficiency Challenges

HydroFLOW® C Range: Limescale Protection for Commercial Buildings (Fits Pipes up to 200mm Outside Diameter)

Optimised for Commercial Use: Designed for offices, hotels, schools, and other commercial buildings.

Reduces Hard Scale Buildup: Helps keep boilers, heat exchangers, and plumbing systems running smoothly.

Improves Energy Efficiency: Enhances heat transfer and reduces fuel consumption.

Chemical-Free & Maintenance-Free: No refills, no filters, just reliable protection.

Ideal for: Offices, schools, hotels, hospitals, and other commercial buildings facing limescale challenges in boilers, heat exchangers, and cooling systems.

HydroFLOW® K40: Optimised Water Quality for Small Pools and Ponds (Fits Pipes up to 63mm Outside Diameter)

Enhanced Filtration & Water Clarity: Improves water quality in pools, hot tubs, and spas.

Reduces Chlorine Demand: Helps lower chlorine levels while maintaining sanitation.

Minimises Water Waste: Lowers backwashing frequency and reduces maintenance costs.

Easy Installation & No Maintenance: Fits externally on pipes, with no modifications required.

Ideal for: Small pools, hot tubs and water features.

HydroFLOW® P Range: Advanced Water Treatment for Commercial Pools and Cooling Towers (Fits Pipes up to 200mm Outside Diameter)

Biofouling and Bacteria Control: Effectively manages biofilm, bacteria, and algae, ensuring cleaner water systems.

Improved Filtration: Keeps filtration systems free from obstructions, enhancing overall efficiency.

Reduced Operational Costs: Optimises system performance, leading to savings in water, energy, and maintenance expenses.

Eco-Friendly & Sustainable: No chemicals, no salts, just efficient water treatment

Ideal for: Commercial swimming pools, spas and cooling towers

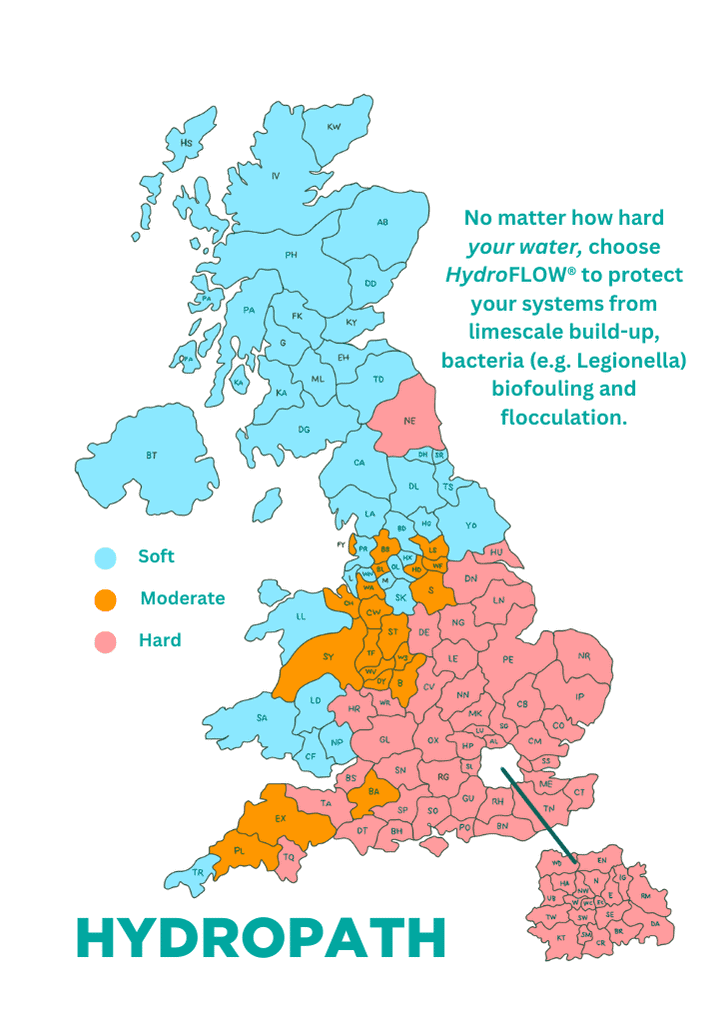

UK Water Hardness Checker

Note: This tool provides an estimate of water hardness based on postcode area. For precise information, please contact your local water supplier.

Let’s Enhance Your Systems with HydroFLOW®

Whether you’re treating scale, controlling biofilm, or improving filtration, HydroFLOW® offers a reliable, chemical-free solution to keep your systems running at their best.

From residential to heavy industry, our award-winning technology supports cleaner operations, reduced maintenance, and long-term sustainability.

Get in touch with us today to discuss how HydroFLOW® can optimise your application.

sales@hydropath.com

+44 (0) 115 986 9966