Industrial Water Treatment with HydroFLOW®

HydroFLOW® delivers advanced water treatment solutions for industrial applications, enhancing operational efficiency and reducing maintenance costs across a wide range of sectors. From power stations and manufacturing plants to food processing and mining operations, our innovative technology helps optimise water system performance, minimise downtime, and lower energy consumption, ensuring reliable and cost-effective operations.

Protecting Vital Infrastructure with Trusted Technology

For over 30 years, Hydropath has been a leader in eco-friendly water treatment for industrial sectors worldwide. Our patented technology addresses critical issues such as limescale, biofouling, corrosion, and bacteria-without relying on chemicals or salts. In industrial environments, untreated water can lead to costly downtime, equipment failure, and increased energy usage. HydroFLOW® offers a sustainable, cost-effective solution to protect valuable infrastructure, enhance system performance, and support efficient, continuous operations.

Common Problems in Industrial Water Systems

Limescale

-

Thick scale reducing flow and heat transfer in production lines, heat exchangers, or steam boilers.

-

Forced shutdowns for mechanical cleaning or acid washes.

-

High chemical dosing regimes raising operational expenses.

-

HydroFLOW® helps by treating process water so mineral crystals have less tendency to attach, cutting downtime and maintenance.

Biofouling

-

Microbial slime in cooling towers, membrane systems, or pipes hindering efficiency.

-

Accelerated corrosion where biofilm shelters certain bacteria.

-

Frequent shock treatments or mechanical scrubbing to restore throughput.

-

HydroFLOW® helps by making it harder for microbes to establish biofilm, reducing reliance on aggressive biocides.

Struvite

-

Accumulation in anaerobic digesters, high-phosphate wastewater lines, or manure/sludge streams.

-

Pump blockages and pipeline restrictions causing system failures.

-

Intensive manual or chemical removal interventions.

-

HydroFLOW® helps by interfering with crystal formation, keeping lines and equipment more open.

Flocculation and Filtration

-

High-solid process waters that overwhelm clarifiers or filters.

-

Large polymer budgets to settle or remove suspended particles.

-

Production slowdowns if filtration or separation is inefficient.

-

HydroFLOW® helps by promoting particle agglomeration, improving separation performance and reducing polymer needs.

Other Scaling

-

Hard deposits in process water lines or injection wells, shrinking throughput.

-

Complex chemical treatments and disposal of spent regenerants.

-

Equipment corrosion or product contamination if scale dislodges erratically.

-

HydroFLOW® helps by reducing how strongly these mineral scales form, maintaining cleaner lines and consistent production.

Cooling Tower

-

Severe scale layers and biofilm in large open-loop towers driving up electricity and water consumption.

-

Substantial blowdowns with chemical-laden discharge.

-

Heightened risk of legionella or other bacterial hazards.

-

HydroFLOW® helps by distributing an electrical signal that minimises scale and microbial fouling, helping maintain efficient cooling cycles.

Sea Water Cooling

-

Rapid biofouling from marine organisms (algae, shellfish) and high mineral scaling in coastal or offshore facilities.

-

Corrosion of metallic surfaces due to salt exposure and under-deposit attack.

-

Regular diver-based cleaning or strong chemical treatments for heat exchangers and pipelines.

-

HydroFLOW® helps by deterring scale and biofilm adherence, helping reduce the frequency and intensity of mechanical or chemical cleanings.

Oil Cooler

-

Scaling or fouling in oil-to-water heat exchangers for turbines, hydraulic systems, or heavy machinery.

-

Overheating risks if deposits insulate heat-transfer surfaces.

-

High labour costs for chemical flushes or manual descale.

-

HydroFLOW® helps by continuously treating the coolant water, reducing mineral buildup and preventing costly breakdowns.

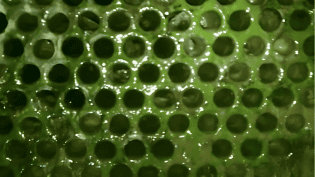

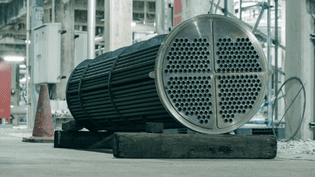

Heat Exchanger

-

Fouling on large plates or tubes in power plants, refineries, or manufacturing lines.

-

Energy losses and output dips as heat transfer efficiency falls.

-

Recurrent cleaning outages that disrupt production.

-

HydroFLOW® helps by making it harder for scale and biofilm to bond on exchanger surfaces, prolonging clean operation intervals.

Heaters and Boilers

-

Multi-mineral scale constricting steam generation or hot-water production, risking tube failures.

-

Excessive blowdown and chemical dosing to maintain safe water chemistry.

-

Safety concerns if thick scale pockets form hot spots.

-

HydroFLOW® helps by treating boiler feedwater so that scale forms less aggressively, stabilising steam output and lowering chemical use.

Electric Resistance & Immersion Heaters

-

Heavy scaling on large immersion rods in process tanks or test baths, leading to uneven temperatures.

-

Frequent element burnouts if heat transfer is compromised.

-

Production slowdowns or quality issues if the heating process becomes unreliable.

-

HydroFLOW® helps by reducing mineral adhesion on elements, helping maintain stable temps and extending heater life.

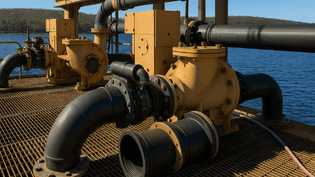

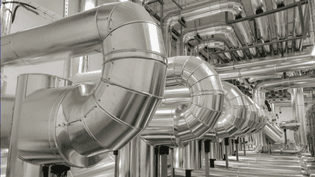

Pipelines

-

Scale or biological deposits narrowing large industrial pipelines, increasing pump loads.

-

Production interruptions if flows drop below required levels.

-

Costly pigging operations or spool replacements.

-

HydroFLOW® helps by generating a signal through the water that hinders deposit buildup, keeping pipelines clearer for consistent throughput.

Valves

-

Scale-encrusted valves failing to open/close fully, leading to leaks or poor flow control.

-

Increased maintenance or replacements if deposits wear down valve seats.

-

Safety hazards if a key control valve sticks under operational stress.

-

HydroFLOW® helps by limiting mineral and biofilm accretion on valve surfaces, improving reliability and reducing downtime.

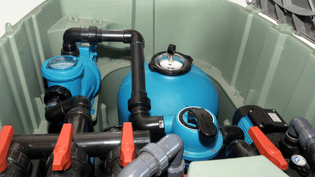

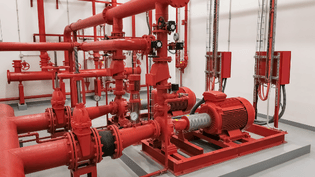

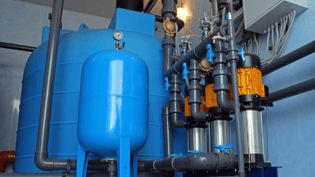

Pumps

-

Scale, silt, or slime eroding impellers and seals in cooling or process water pumps.

-

Higher electricity usage and risk of catastrophic failures.

-

Unplanned maintenance stops that disrupt production scheduling.

-

HydroFLOW® helps by treating the water to reduce deposits, preserving efficient flow and helping extend pump service intervals.

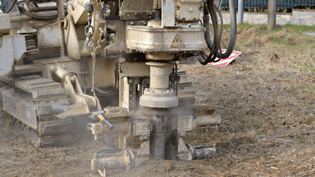

Wells and Boreholes

-

Iron or hardness fouling submersible pumps in high-capacity production wells, lowering yield.

-

Repeated acid treatments or downtime to restore pump performance.

-

Pressure to drill new wells if output declines significantly.

-

HydroFLOW® helps by inhibiting mineral buildup on well screens and pump components, maintaining more stable extraction rates.

Centrifuges

-

Scale and sludge accumulation in dewatering or separation centrifuges, causing vibration and decreased efficiency.

-

Frequent tear-downs for manual cleaning and rebalancing.

-

Excess labour and chemical costs to keep throughput on target.

-

HydroFLOW® helps by discouraging solids from sticking to rotating bowls, improving separation quality and reducing shutdowns.

Polymer Reduction in Dewatering

-

High polymer expense in sludge dewatering (tailings, heavy waste) to achieve dryness.

-

Wet sludge leading to extra hauling or disposal fees.

-

Belt press or centrifuge slowdowns if more chemical is required.

-

HydroFLOW® helps by improving floc formation, so less polymer is needed to extract water effectively from sludge.

Dissolved Air Flotation (DAF)

-

Large-scale DAF systems managing industrial wastewater with high FOG or solids.

-

Thick scum layers and chemical overuse if flotation efficiency lags.

-

Regular tank cleaning shutting down part of the treatment process.

-

HydroFLOW® helps by helping suspended particles attach to air bubbles more effectively, easing the flotation step and lowering reagent dosage.

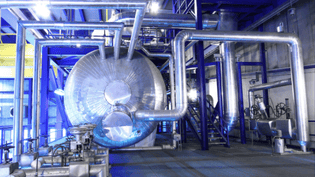

Steam Boiler

-

Serious scale limiting heat transfer in high-pressure boilers or steam turbines, undermining efficiency.

-

Frequent blowdowns and chemical feeds to maintain steam quality.

-

Risk of tube ruptures or downtime if deposits accumulate unchecked.

-

HydroFLOW® solves by treating the feedwater, making scale less tenacious on boiler tubes, preserving performance and safety.

High Concentration Process

-

Evaporators or concentrate loops with extremely high TDS prone to severe scaling.

-

Repeated forced downtime for mechanical or chemical descale, delaying production.

-

High chemical usage or compromised product quality if scaling interrupts the process.

-

HydroFLOW® solves by helping reduce scale deposition under elevated TDS conditions, maintaining consistent throughput and minimising cleaning intervals.

Corrosion Control

-

Under-deposit or microbial-induced corrosion in high-temperature or high-flow systems.

-

Leaks, bursts, or contamination events requiring major repairs.

-

Significant capital costs to replace corroded infrastructure.

-

HydroFLOW® solves by minimising scale and biofilm layers that often accelerate corrosion, prolonging equipment life.

Reverse Osmosis

-

Membrane fouling in large RO plants (desalination, boiler feed, or process water), raising CIP frequency.

-

Reduced water recovery and bigger brine disposal problems if scale forms on membranes.

-

Rapid membrane turnover driving up operating expenses.

-

HydroFLOW® solves by making scale crystals less likely to cling to RO membranes, extending membrane life and stabilising performance.

Filters

-

Rapid clogging of sand or multimedia filters in cooling water or process streams, limiting flow and efficiency.

-

Frequent backwashing or media replacement intervals, driving up operational costs.

-

Potential production disruptions if water clarity or throughput fall below required specifications.

-

HydroFLOW® solves by promoting flocculation and discouraging biofilm formation, allowing filters to capture solids more effectively and extend run times before changeouts.

Legionella Treatment

-

Risks in extensive cooling towers, hot water loops, or storage tanks where water stagnates.

-

Regulatory or safety liabilities if legionella is detected.

-

Intensive disinfection protocols and water temperature management to limit bacterial growth.

-

HydroFLOW® helps by disturbing biofilm surfaces where legionella multiply, aiding control efforts without constant chemical shocks.

Enhance Industrial Efficiency by Addressing Limescale and Biofouling

I Range Heavy-Duty Water Treatment for Industrial Applications (Fits Pipes up to 200mm Outside Diameter)

Optimised for Industrial Water Systems – Helps maintain boilers, heat exchangers, and process water systems.

Addresses Limescale and Hard Mineral Deposits – Reduces buildup in pipelines and critical equipment, improving efficiency.

Biofouling & Corrosion Control – Reduces bacteria and algae growth, extending equipment lifespan.

Improves Water Quality – Enhances filtration efficiency and minimises sediment buildup in industrial systems.

Ideal for: Manufacturing plants, food processing, power stations, and other industrial water systems.

Custom Range Tailored Solutions for Large-Scale Industrial Applications (Fits Pipes from 220mm to several meters Outside Diameter)

Bespoke Water Treatment Solutions – Designed for pipes larger than 220mm, accommodating unique industrial needs.

Addresses Limescale & Biofouling – Helps maintain efficiency in extreme water conditions and reduces maintenance costs.

Scalable & Adaptable – Custom units available for wastewater treatment, aquaculture, cooling towers, and specialised applications.

Seamless Integration – Custom units fit into any existing system, ensuring maximum performance and efficiency.

Ideal for: Large-scale industries, municipal water treatment, power plants, and custom industrial applications.

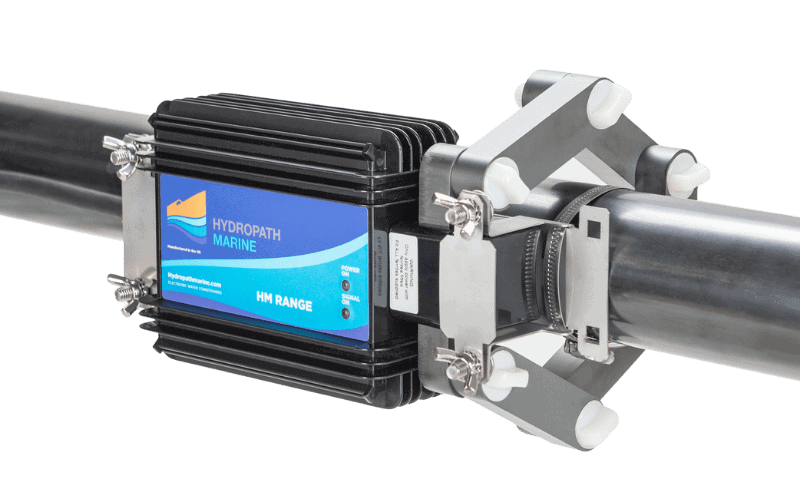

HM Range Advanced Water Treatment for Marine Applications (Fits Pipes from 25mm and Above)

Designed for Marine Environments – Optimised for vessels, offshore platforms, and marine water systems handling seawater, freshwater, or brackish water.

Controls Limescale & Hard Mineral Buildup – Helps maintain desalination plants, engine cooling systems, heat exchangers, and piping networks.

Reduces Biofouling and Corrosion – Inhibits algae, biofilm, and barnacle formation, protecting vital equipment and extending system lifespan.

Eco-Friendly & Chemical-Free – Treats water without chemicals, reducing environmental impact and ongoing treatment costs.

Ideal for: Cargo ships, cruise liners, naval vessels, offshore oil platforms, and marine water treatment facilities.

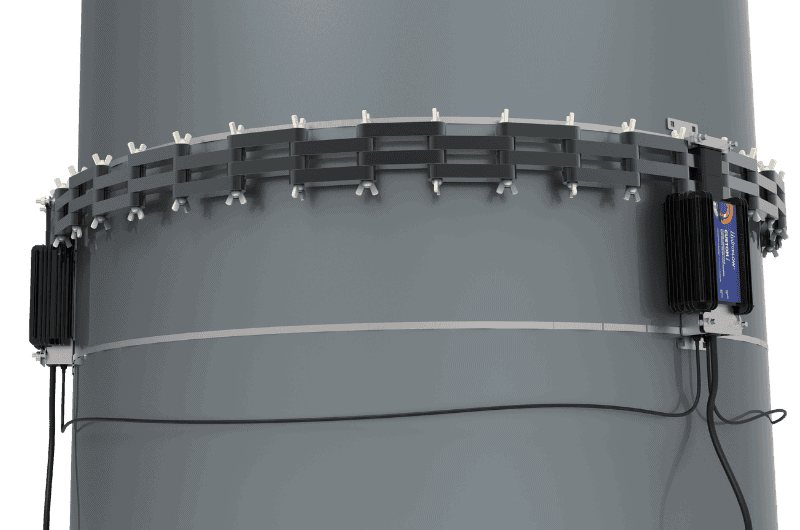

Multihead Water Treatment for Demanding Industrial Applications

Tailored Multihead Solutions – Multihead is engineered for pipes larger than 220mm, providing customised treatment for complex and large-scale industrial systems.

Comprehensive Limescale and Biofouling Control – Multihead treats hard mineral scaling and disrupts biofilm formation, ensuring high efficiency.

Fully Scalable and Adaptable – Multihead units are configurable for diverse applications, including wastewater treatment, aquaculture, cooling towers, desalination plants, and specialist industrial processes.

Seamless Retrofit and Integration – Designed to integrate effortlessly into existing infrastructure without system interruption, maximising operational performance.

Ideal for: Power plants, municipal water treatment facilities, industrial manufacturing, offshore platforms, and custom-engineered water systems.

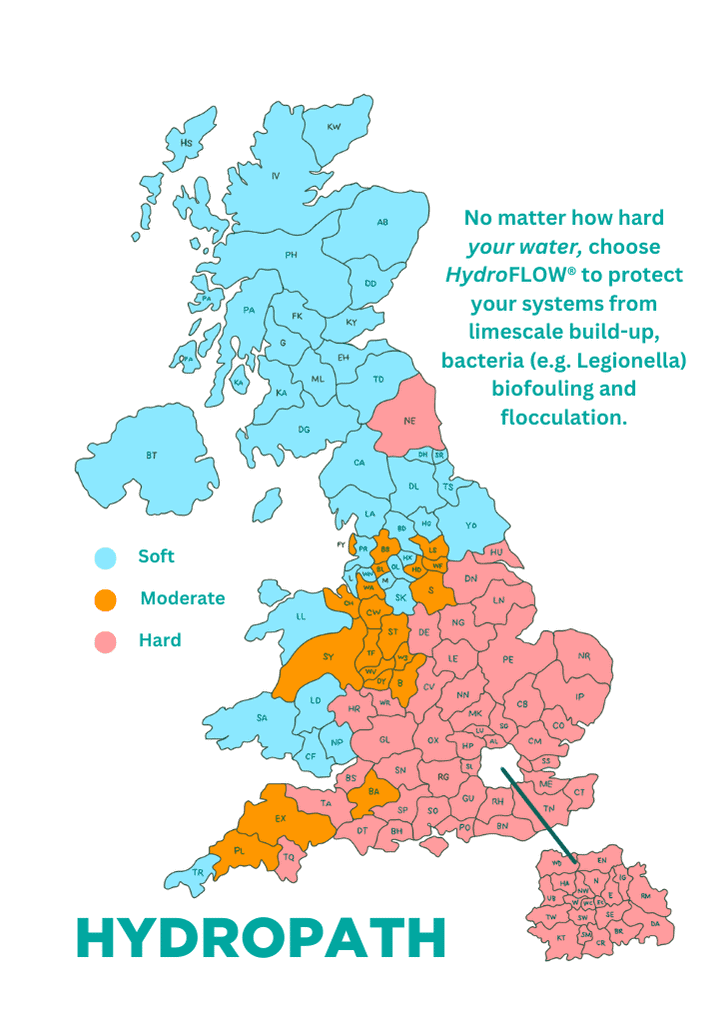

UK Water Hardness Checker

Note: This tool provides an estimate of water hardness based on postcode area. For precise information, please contact your local water supplier.

Let’s Enhance Your Systems with HydroFLOW®

Whether you’re treating scale, controlling biofilm, or improving filtration, HydroFLOW® offers a reliable, chemical-free solution to keep your systems running at their best.

From residential to heavy industry, our award-winning technology supports cleaner operations, reduced maintenance, and long-term sustainability.

Get in touch with us today to discuss how HydroFLOW® can optimise your application.

sales@hydropath.com

+44 (0) 115 986 9966